TM 9-2320-279-34-1

Change 5

6-14.9

Electrical System Maintenance Instructions (Cont)

(2)

Dry stator and rotor with compressed air or dry cloth.

(3)

Clean all other components, except bearings, in dry cleaning solvent.

(4)

Inspect electrical assemblies for damage, frayed or bare wires, or loose connections.

(5)

Inspect mechanical assemblies for damage. Check for old or excess grease.

(6)

Clean rectifier assembly holes and terminal screws to ensure good electrical contact.

(7)

Clean carbon coating off slip rings with crocus cloth

(8)

Inspect brushes for burnt appearance, cracks, broken edges.

(9)

Check brush wear and replace if length measures less than 0.19 in. (4.8 mm).

(10)

Check drive end housing bearing for

smooth rotation. If bearing binds,

replace bearing.

(11)

Check slip ring housing bearing for

missing rollers. If rollers are missing,

replace bearing.

d. Assembly.

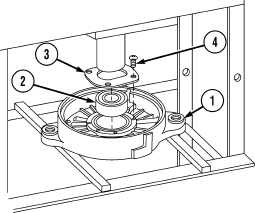

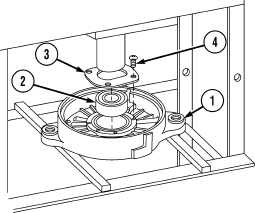

(1)

Position drive end housing (1) in press.

CAUTION

Apply pressure only on outer portion of race

when pressing bearing into drive end housing.

Failure to comply may result in equipment

damage.

(2)

Press bearing (2) in drive end housing

(1).

(3)

Install bearing retainer (3) in drive end

housing (1) with four screws (4).

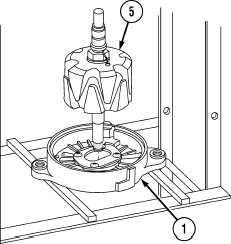

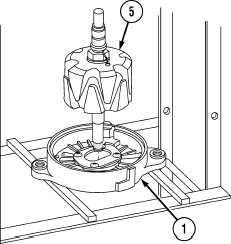

NOTE

Threaded end of shaft must point downward.

(4)

Install rotor assembly (5) in drive end

housing (1).

(5)

Remove rotor assembly (5) from press.