TM 5-5420-234-14&P

5-5.

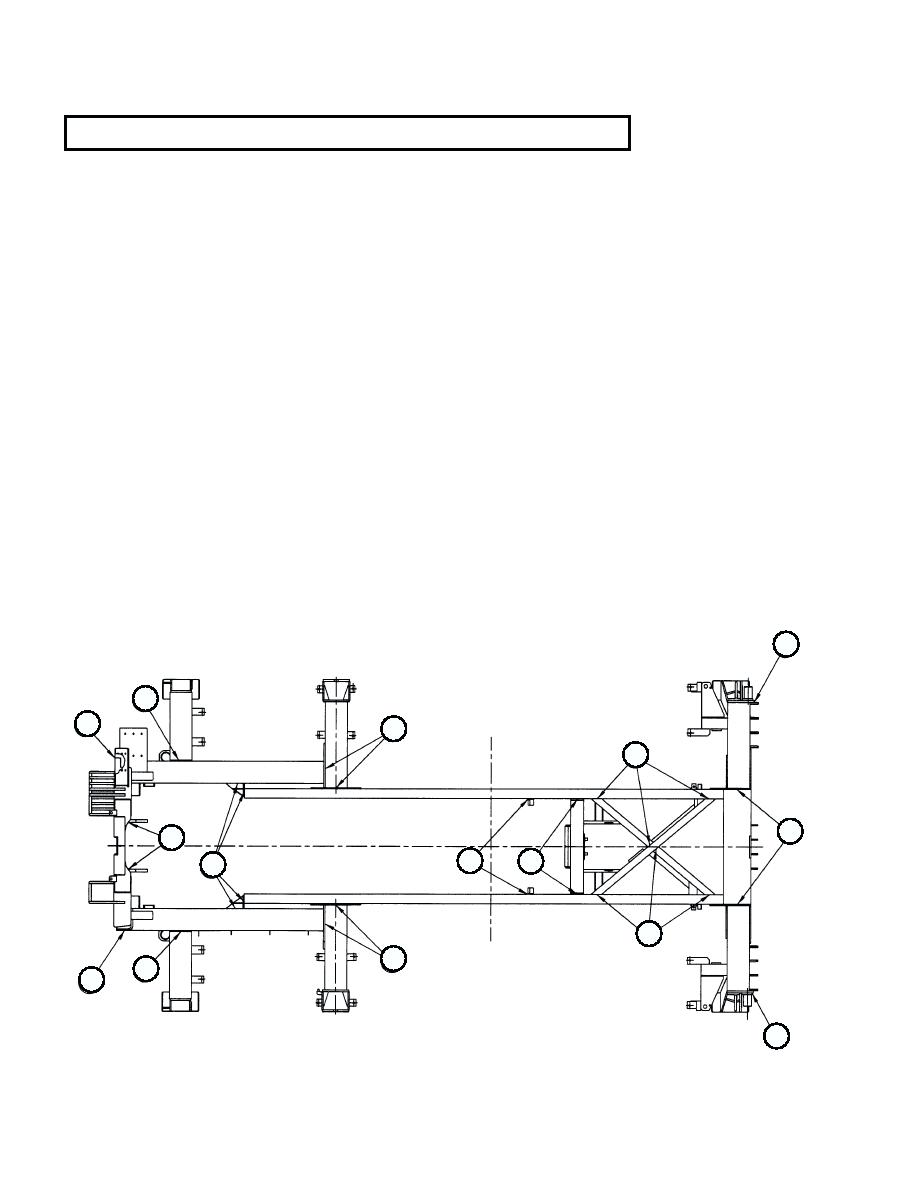

BAP GENERAL WELDING MAINTENANCE (continued).

(8)

Center Roller Crossmember to Main Rails. These welds join the center roller crossmember tube to the

main rails. Sound welds in these joints are necessary to ensure support of the loaded BAP during

handling and transport. A crack should be repaired before it reaches 1.0 inch (25.4 mm) in length. The

combined length of multiple cracks at either of the rail joints should not exceed 1.5 inches (38.1 mm).

(9)

X-Bracket to X-Brace and to Main Rails. These welds join x-brace members and join x-braces to main

rails. Sound welds in these joints are necessary to ensure that the frame, with load, will remain square

during handling and transport. A crack should be repaired before it reaches 1.0 inch (25.4 mm) in

length. The combined length of multiple cracks at any one of the x-brace joints should not exceed 2.0

inches (50.8 mm).

(10)

Rear Beam Outrigger Tubes to Main Rails. These welds join rear beam outrigger tubes to gusset plates,

which join to main rails and to beam center segment. Sound welds in these joints are necessary to

ensure safe support of bridge bays during handling and transport as well as supporting loaded BAP

when resting on BAP rear feet. A crack should be repaired before it reaches 1.5 inches (38.1 mm) in

length. The combined length of multiple cracks at any one joint should not exceed 2.0 inches (50.8

mm).

(11)

Rear Roller Axles to Beam End Plates. These welds join rear roller axles to beam end plates. Sound

welds in these joints are necessary to ensure safe support of bridge bays during handling and transport.

A crack should be repaired before it reaches 1.0 inch (25.4 mm) in length. The combined length of

multiple cracks at either of the axle joints should not exceed 1.5 inches (38.1 mm).

11

4

1

5

9

10

3

7

8

6

9

5

4

1

11

5-70