TM 9-2320-279-34-1

Axles No. 1 and No. 2 Maintenance instructions (Cont)

WARNING

Adhesives, solvents, and sealing compounds can burn easily, can give off

harmful vapors, and are harmful to skin and clothing. lb avoid injury or

death, keep away from open fire and use in well-ventilated area. If

adhesive, solvent, or sealing compound gets on skin or clothing, wash

immediately with soap and water.

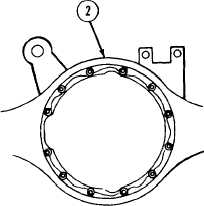

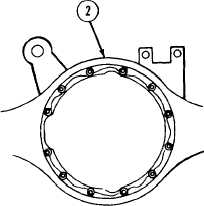

(3)

Apply silicone adhesive-sealant on inside edge of axle

housing (2) mounting surface.

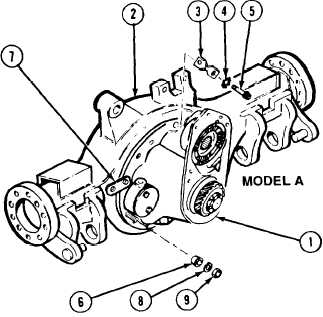

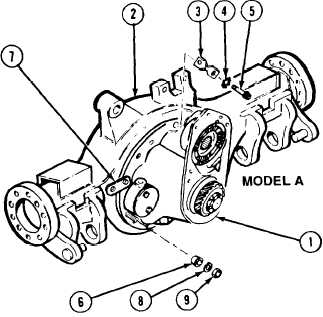

(4)

Soldier A installs differential carrier (1) in

axle (2) while Soldier B operates lifting

device.

(5)

Install bracket (3), two lockwashers (4),

and screws (5).

(6)

Install four tapered dowels (6).

(7)

Install two brackets (7), 10

lockwashers (8), and nuts (9).

(7.1) Install two brackets (7) and six

lockwashers (4) and screws (5).

(7.2) Install four tapered dowels (6),

lockwashers (8), and nut (9).

(7.3) Install bracket (3), two lockwashers (4),

and screws (5).

(7.4) Tighten all screws to 180 lb-ft (244 N•m).

(8)

Tighten screws (5) to 210 to 230 lb-ft (285

to 312 N•m).

(9)

Tighten nuts (9) to 150 to 170 lb-ft (203

to 231 N•m).

d.

Follow-on Maintenance.

(1)

Install differential carrier cover (para 9-8).

(2)

Install axle housing cover assembly, No. 2 (para 9-5).

(3)

Install axle No. 2 (para 9-4).

END OF TASK

Change 3

9-37