TM 9-2320-279-34-2

Winch Maintenance Instructions (Cont)

f. Adjustment.

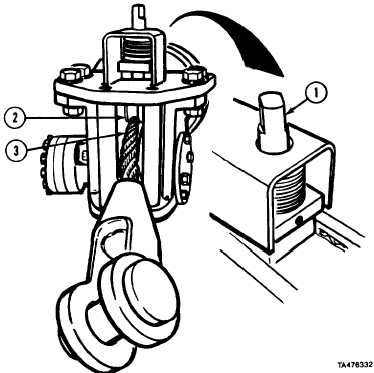

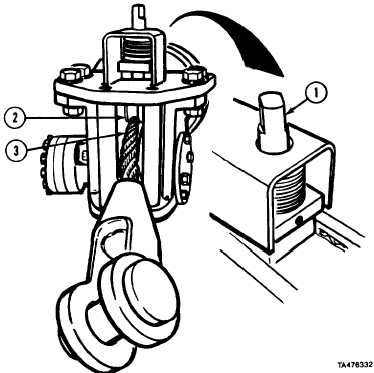

(1) Turn stud (1)

counterclockwise until

roller (2) does not contact

cable (3).

Turn stud (1) clockwise until

roller (2) just contacts

cable (3) then turn stud

clockwise eight more turns.

(2)

g. Follow-on Maintenance.

(1) Lubricate fairlead

(LO 9-2320-279-12).

(2) Install fairlead motor

(TM 9-2320-279-20).

END OF TASK

16-11. HEAVY-DUTY WINCH REPAIR (M984).

This task covers:

a. Disassembly

c. Assembly

b. Cleaning/Inspection

d. Follow-on Maintenance

INITIAL SETUP

Models

Personnel Required

M984

MOS 63W, Wheel vehicle repairer (2)

Test Equipment

References

None

None

Special Tools

Equipment Condition

None

TM or Para

Condition Description

Fabricated Tools

Para 16-10

Heavy-duty winch removed.

Detent ball compression tool, Item 3,

Para 16-16

Heavy-duty winch brake

Appendix B

installed.

Supplies

Special Environmental Conditions

Oil, lubricating, Item 46, Appendix C

None

Solvent, dry cleaning, Item 57, Appendix C

Adhesive-sealant, silicone, Item 6, Appendix C

General Safety Instructions

Grease, general purpose, lithium base,

None

Item 36, Appendix C

Level of Maintenance

General Support

16-25