TM 5-5420-234-14&P

5-2. DIRECT SUPPORT TROUBLESHOOTING (continued).

7.

BAP WINCH DOES NOT OPERATE (continued).

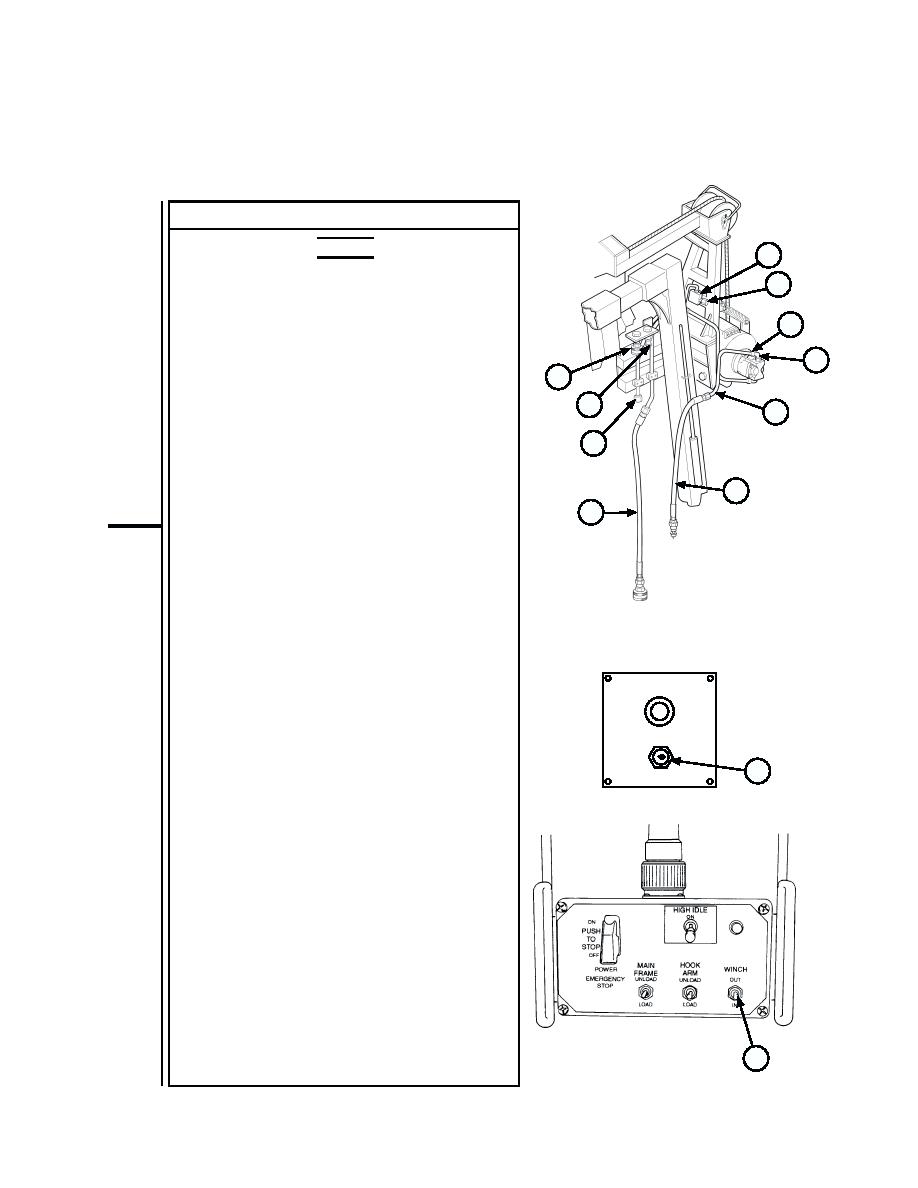

VALVE BLOCK BYPASS

WARNING

4

The LHS hydraulic system operates at oil

5

pressures up to 3625 psi (24,994 kPa). Never

disconnect any hydraulic line or fitting with-

1

out first dropping pressure to zero. Failure

to comply with this warning may result in

serious injury or death to personnel.

2

7

(1)

Loosen tube nut (1) at winch motor elbow (2).

(2)

Remove inlet tube (3) from valve block (4).

10

3

NOTE

8

It may be necessary to loosen elbow on winch

motor in order to fully rotate tube downward.

6

(3)

Rotate inlet tube (3) downward.

9

(4)

Tighten tube nut (1) on winch motor elbow (2).

(5)

Install plug (5) on valve block (4).

(6)

Remove male quick-disconnect hose (6) from

dummy coupling (7). Remove opposite end of

hose (6) from tube nut (8).

( 7 ) Install male quick-disconnect hose (6) on inlet

tube (3).

( 8 ) Remove female quick-disconnect hose (9) from

dummy coupling (10).

( 9 ) Attach two quick-disconnect hoses (6 and 9) to

Transporter.

( 1 0 ) Start engine.

PTO ENGAGE

( 1 1 ) Turn PTO ENGAGE switch (11) to ON.

NOTE

Oil will leak from hydraulic tubing when the

11

OFF

ON

WINCH switch is in the neutral position. Place

drain pan under tubing to collect oil.

( 1 2 ) Move WINCH switch (12) to the OUT position,

then to the IN position while observing winch

operation.

( 1 3 ) Turn PTO ENGAGE switch (11) to OFF position.

( 1 4 ) Shut off engine.

( 1 5 ) Install female quick-disconnect hose (9) on

dummy coupling (10.

( 1 6 ) Remove male quick-disconnect hose (6) from

inlet tube (3).

( 1 7 ) Install male quick-disconnect hose (6) on tube

nut (8).

( 1 8 ) Install male quick-disconnect hose (6) on dummy

coupling (7).

( 1 9 ) Remove plug (5) from valve block (4).

( 2 0 ) Loosen tube nut (1) on winch motor elbow (2).

( 2 1 ) Rotate inlet tube (3) upward.

12

( 2 2 ) Install inlet tube (3) on valve block (4).

( 2 3 ) Tighten tube nut (1) on winch motor elbow (2).

5-47