TM 5-5420-234-14&P

5-2. DIRECT SUPPORT TROUBLESHOOTING (continued).

6.

MAIN FRAME, HOOK ARM, AND WINCH DO NOT OPERATE OR OPERATE

SLOWLY (continued).

HYDRAULIC SYSTEM PRESSURE TEST

WARNING

The LHS hydraulic system operates at

oil pressures up to 3,625 psi (24,994

kPa). Never disconnect any hydraulic

line or fitting without first dropping

pressure to zero. Failure to comply

with this warning may result in serious

injury or death to personnel.

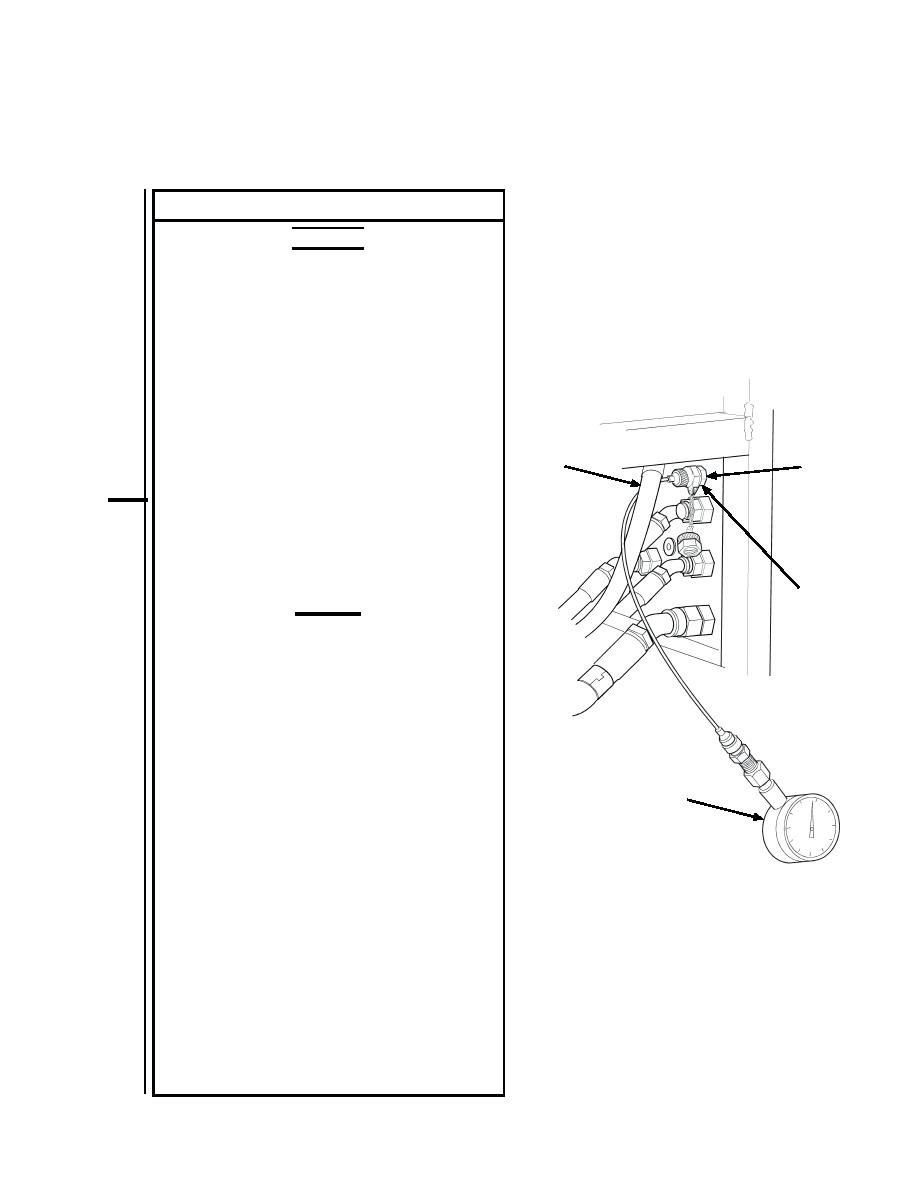

(1) Remove plug and O-ring from port TPP on

main hydraulic block assembly.

(2) Install hose adapter, hose, and pressure

gage on main hydraulic block assembly.

TEST PORT

HOSE

(3) Start engine and engage the PTO.

TPP

(4) Turn the light control switch to the STOP

LIGHT position. Place LHS MODE

SELECT switch in the HOOK ARM ONLY

(manual mode) position.

(5) Attempt to operate the LHS and/or winch

using the remote control or cab controls.

HOSE

ADAPTER

CAUTION

Fully extending or retracting hydrau-

lic cylinders will put the hydraulic

system into relief. This should be

limited to 10 seconds. Failure to com-

ply with this caution may result in

damage to equipment.

NOTE

Full relief pressure of 3,100 to 3,300 psi

GAGE

will be reached during the full extension

of the hydraulic cylinder.

(6) Observe the readings on the pressure gage

during loading.

(7) Shut off engine and turn the light control

switch to the OFF position.

NOTE

If 3,100 to 3,300 psi were not obtained,

skip the remaining steps in this test and

go to Step 3.

(8) Remove hose adapter, hose, and pressure

gage from main hydraulic block assembly

(9) Install plug and O-ring in port TPP on main

hydraulic block assembly.

5-41